首页 > PRODUCTS > SCREEN PRINTING SYSTEM > PRINTING MACHINETC106AS Automatic Servo Control Screen Printing Press

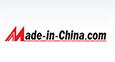

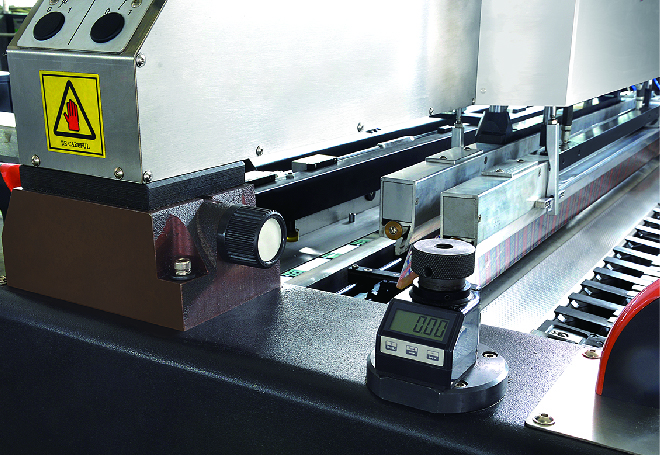

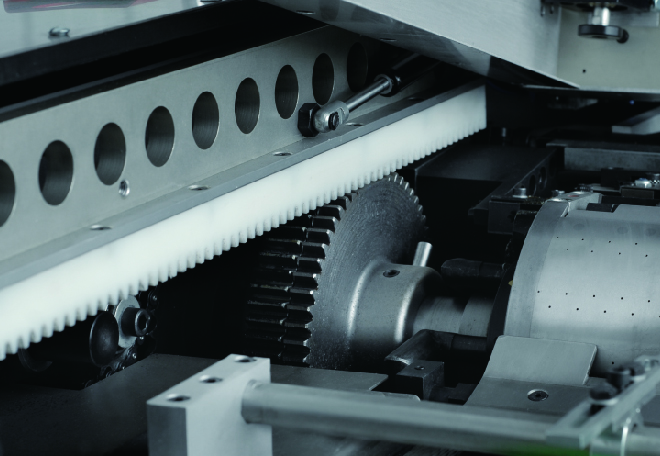

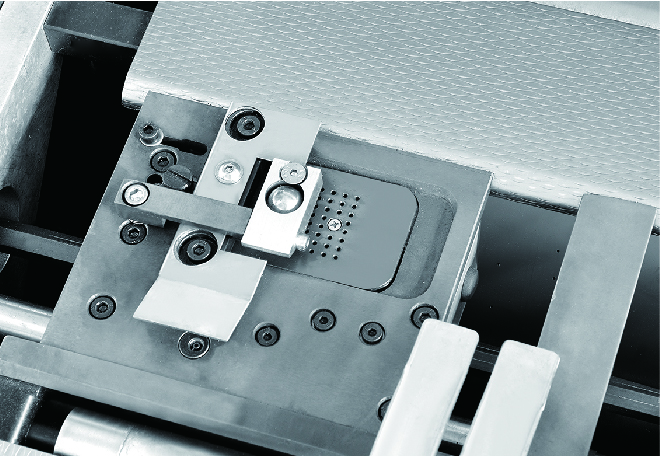

TC-106AS Automatic servo control screen printing press

|

Max sheet size |

1060x750mm |

|

Min sheet size |

560x350mm |

|

Max printing size |

1050x750mm |

|

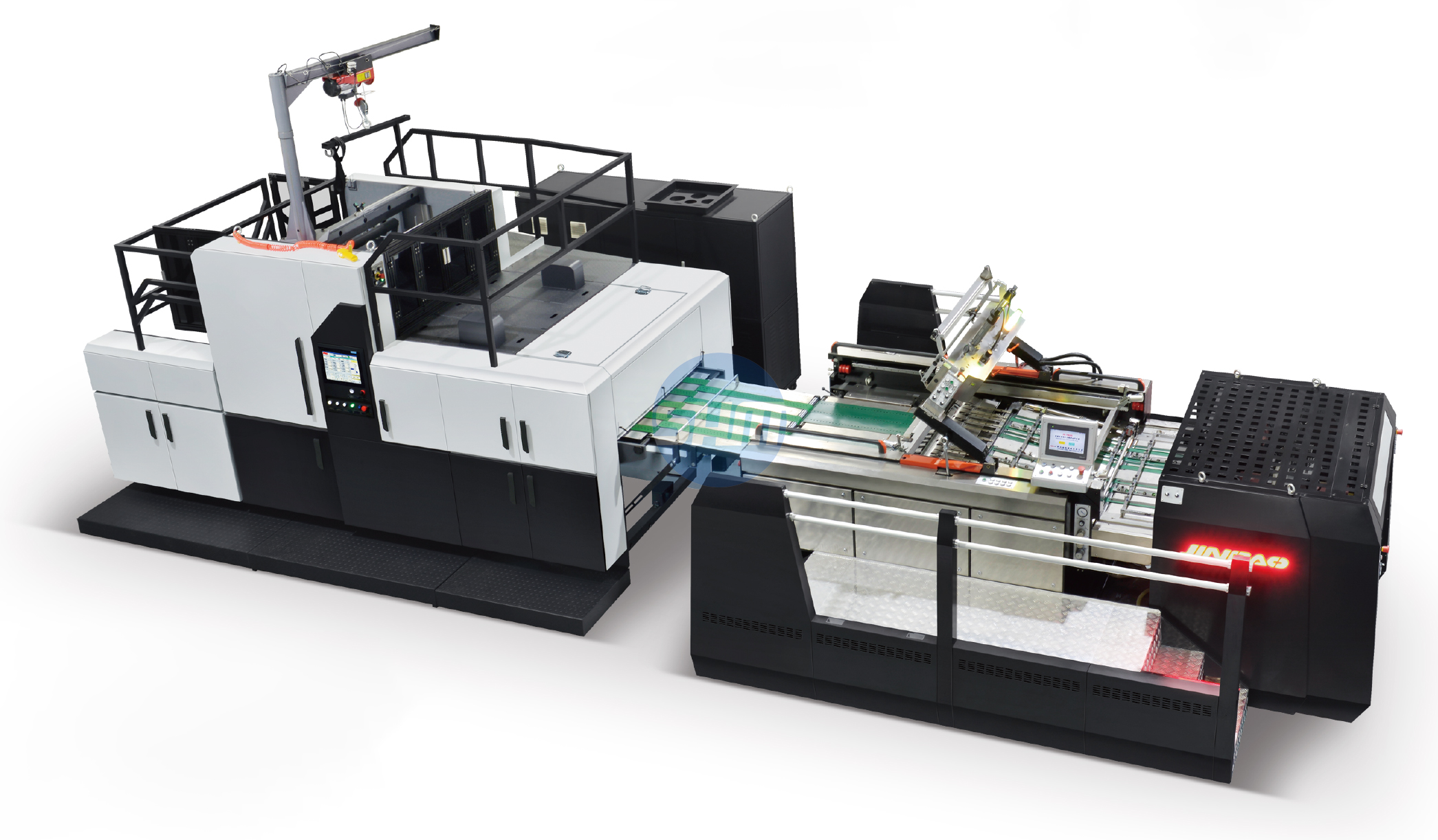

Frame size |

1300x1170mm |

|

Substrate thickness |

90-500gsm |

|

Printing speed |

800-5000 PCH |

|

Power required |

3P 380V 50Hz 24.3kw |

|

Weight |

4600kg |

|

Dimension

|

4850x4220x2050mm

|

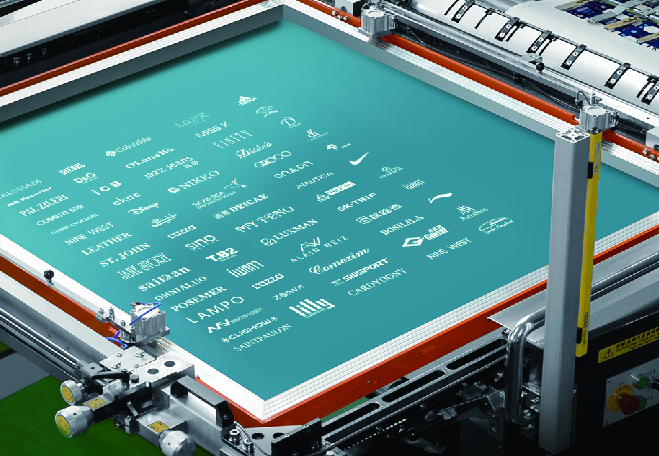

2. Screen Type Cold foil : When JB-104ZJ connect to automatic screen printing machine, major for achieving delicate metallic decoration effect: The paper sheet to be coated with cold foil UV varnish in screen unit, in order to realize the relief similar to 3D cold foil effect .

Remark: Cold foil can be achieved not only first cold foil then printing; But also first printing then cold foil.

|

Model |

TC104ZJ |

|

Working breadth |

Max.740x1040mm Min.393x546mm |

|

Printing area |

Max.730x1030mm |

|

Sheet weight |

90-350g/㎡ |

|

Film roll diameter |

Max.φ500mm |

|

Film width |

Max.1040mm |

|

Speed |

Film transfer:7000sheet/h; Cold stamping:3000sheet/h |

|

UV power |

About 40kw |

|

Total power |

About 85.8kw |

|

Total weight |

About 8000kg |

|

Dimension(LxBxH) |

5600x4800x3800mm |

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356