首页 > PRODUCTS > PAPER PRODUCT SYSTEM > RIGID BOX MACHINERB6040/6040A Automatic Rigid Box Maker

RB6040/6040A AUTOMATIC RIGID BOX MAKER

INTRODUCTION:

Automatic Rigid Box Maker is a good equipment for making high-grade boxes because it is characterized by fine design, reliable performances and advanced technologies. It employs PLC, photoelectric detector system, hydraulic system, HMI to automatically finish feeding and gluing paper, conveying cardboard, forming and gluing four angles of cardboard, positioning and forming box in one time. It is applicable to make high-grade boxes for shoes, shirts, jewelry, gifts, etc.

MAIN FEATURES:

1. Automatic delivery unit for paper feeder.

2. Automatic circulation, mixing and gluing system for hot-melting glue.

3. Hot-melting paper tape automatic conveying, cutting, and finish pasting the inner box quad stayer (four angles) of cardboard in one process.

4. The vacuum suction fan under the conveyer belt can keep the glued paper from deviating.

5. The glued paper and cardboard inner box employ hydraulic rectifying device to spot correctly.

6. The box-forming unit can automatically collect boxes and deliver them according to the boxes convey situation on the conveyer belt.

7. The box-forming unit can continually delivery boxes, wrap sides, fold ears and paper sides and form in one process.

8. The whole machine employs PLC, photoelectric detector system and HMI to automatically form boxes in one process.

9. It can automatically diagnose the troubles and alarm accordingly.

MAIN SPECIFICATIONS:

|

Model |

RB6040 |

RB6040A |

|

Paper size |

Max.610x850mm Min.120x250mm |

Max.610x850mm Min.120x250mm |

|

Paper thickness |

100-200g/m2 |

100-200g/m2 |

|

Cardboard thickness |

0.8-3mm |

0.8-3mm |

|

Finished product (box) size |

Max.600x400x150mm Min.100x50x12mm |

Max.600x400x150mm Min.100x50x12mm |

|

Folded paper size |

10-35mm |

10-60mm |

|

Precision |

±0.5mm |

±0.5mm |

|

Production speed |

Max.35sheets/min |

Max.35sheets/min |

|

Power |

16.35kw 380V 3phase |

16.35kw 380V 3phase |

|

Weight |

6800kg |

6800kg |

|

Dimension |

6600x4100x3250mm |

6600x4100x3250mm |

LONG EAR FOLDING DEVICE(OPTIONAL)

lt can fold the ear size 1/2 Width and 1 Width of box.(Width≤100mm)

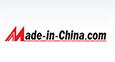

MECHANICAL TYPE PAPER FEEDER

Adopt on-line mechanical type paper feeder with simple structure and steady running.

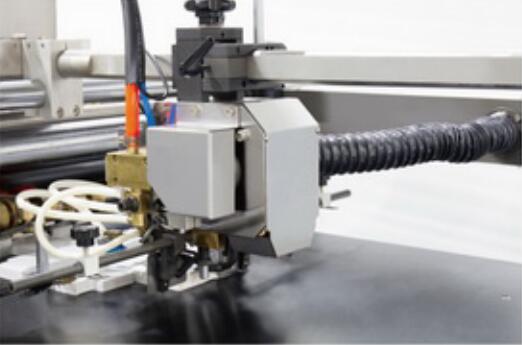

ALL ICONS CONTROL PANEL

Friendly-designed all icons control panel, easy to understand and operate.

HYDRAULIC RECTIFYING POSITIONING DEVICE

Adopt imported hydraulic rectifying system and photoelectric device for positioning, which efficiently improves the precision.

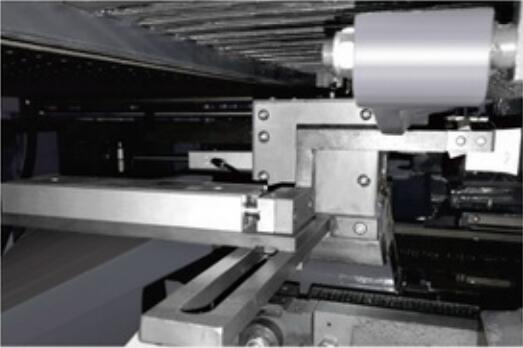

AUTO PASTING BOX FOUR CORNERS

Adopt environment-friendly tape to paste the box corners, which can paste four corners in one process with neat appearance.

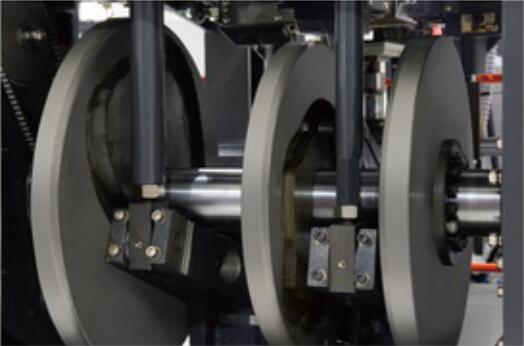

QUALITY DISC CAM

Adopt durable alloy steel disc cams.

Copyright © 2012 SHM INTERNATIONAL 沪ICP备12034060号-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356