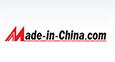

首页 > PRODUCTS > PAPER PRODUCT SYSTEM > FOLDER GLUER MACHINERT1100 Automatic Window Patching Machine

RT1100 AUTOMATIC WINDOW PATCHING MACHINE

INTRODUCTION:

Automatic window machine is the most advanced domestic window machine model, which is the only one reach maximum 1100*920mm. Perfect humanized design concept makes this machine have high efficiency. High precision. characteristics such as high stability and simple operation. This machine can be used for paper jam and corrugated paper, using no stop to give paper to the bottom of the way to separate sheet pile of paper. Through push gauge positioning, flexo module printing glue, stable and accurate diaphragm cut and cross knife cut, it can achieve film function for pair tissue box, gift boxes, toy box, shirt box, milk box and other windows.

Host frame adopts Shougang 30 mm steel plate, which made through heat treatment qualitative and NC machine tool processing, ensure smooth operation and stable quality of machinery. Mechanical distributes five parts of feeding paper, positioning, gluing, filming and delivering paper.

The paper part uses the United States imported Ever-power brand deep-slot type feeder belt, with our company's unique support plate type intermittent paper to ensure smooth and smooth, not easy to double, empty sheet. so that the speed of the whole machine is increased to 7000 sheets per hour, the suction belt and the paper collection conveyor belt use the imported siglin belt. The mechanical transmission chain all uses the Japanese sign and the chain. mechanical key parts using Japanese seiko (NSK) bearings up to 50%. The control part button uses Germany Schneider, the man-machine interface uses Taiwan Willon, the PLC frequency transformer uses Taiwan Delta, each photoelectric switch uses OMRON, the motor uses Taiwan Dongyuan variable frequency speed motor. The control part to achieve 95% import. This machine has reasonable design, stable quality, simple operation and easy learning. is a good helper in your printing and packaging business.

MAIN SPECIFICATIONS:

|

Model |

RT1100 |

|

Sheet size |

Max.1100x920mm Min.80-100mm |

|

Window size |

Max.840x500m Min.30x45mm |

|

Sheet thickness |

Cardboard 200-2000g/m² Corrugated board 1-6mm |

|

Film thickness |

0.03-0.2mm |

|

Accuracy |

Left/right ±0.5mm Top/bottom ±1mm |

|

Weight |

3300kg |

|

Speed |

About 10000p/h |

|

Power |

3kw |

|

Dimension |

4225x1700x1500mm |

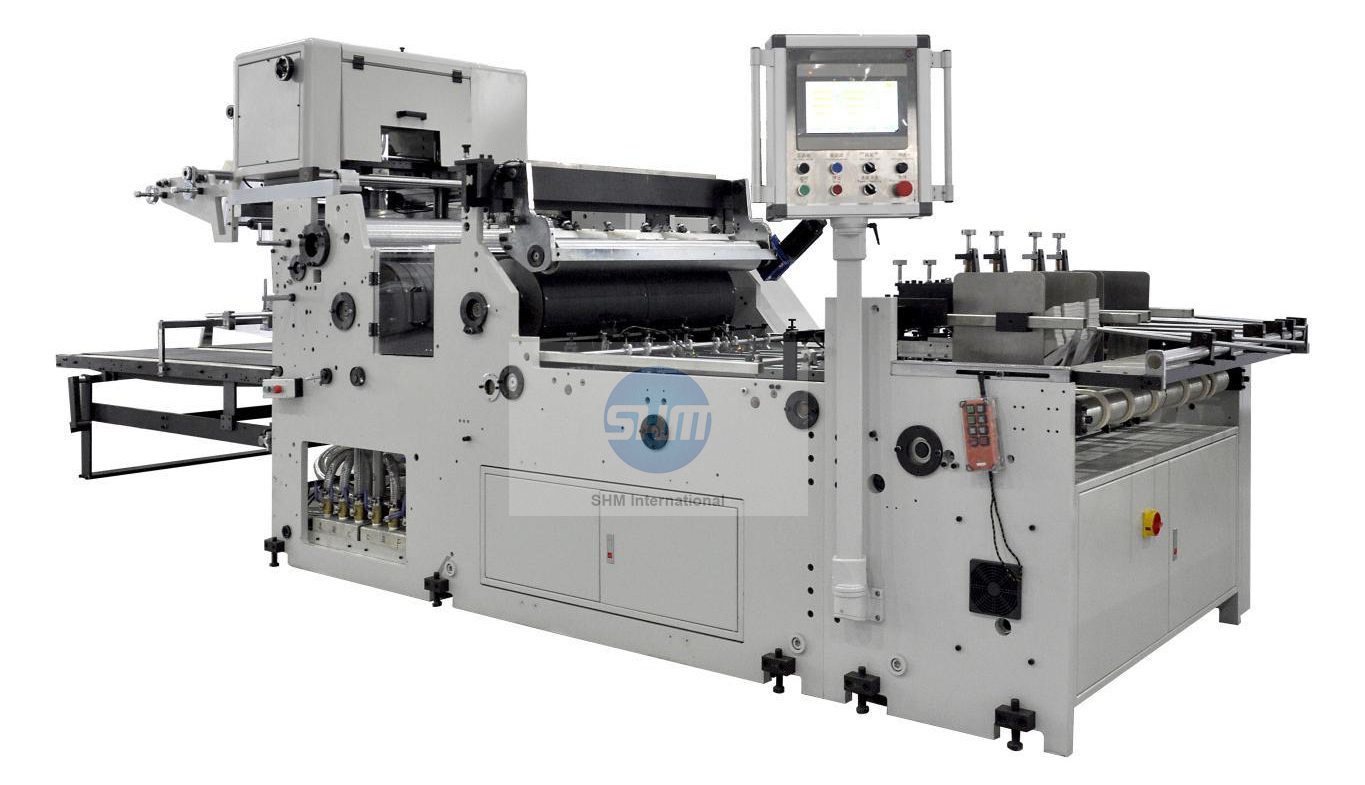

FEEDING SYSTEM

Equipped with lower belt feeding system, with the choice of option which is piling lifting system and belt lifting system.

The characteristic of the belt lifting system is high speed thus increasing capacity.The characteristic of the piling lifting system is that the feeding belt can be run continuously while boxes can go through the upward/downward movable piling lifting system. This piling lifting system is flexible in capable of feeding different boxes without scratching the boxes.

Our feeding system design is an advance technology. Synchronous belt feeder is equipped with suction system. At the chain adjusting section there are four feeding chains.

There is a feeding gate at the feeder which allows you to adjust upper rail without additional tool. This upper rail is made of flat steel and is connected to the middle part of the frame.

GLUING SECTION

Gluing section consists of the chrome-plated glue roller, glue separation plate, side guide and gluing mould

The gluing section can be pulled out easily for setting and cleaning

The glue separation plate is adjustable to control the amount and area of glue

If the machine stops, the cylinder will lift the glue roller and then driven by another motor to avoid leaking of glue Option of pre-make ready table is available. Operator can set up the mould outside of the machine

This system is reliable which ensure the registration of rail, cardboard and chain is accurate. Even when there is serious jam, the position is precise and you can use micro-adjustment to adjust.

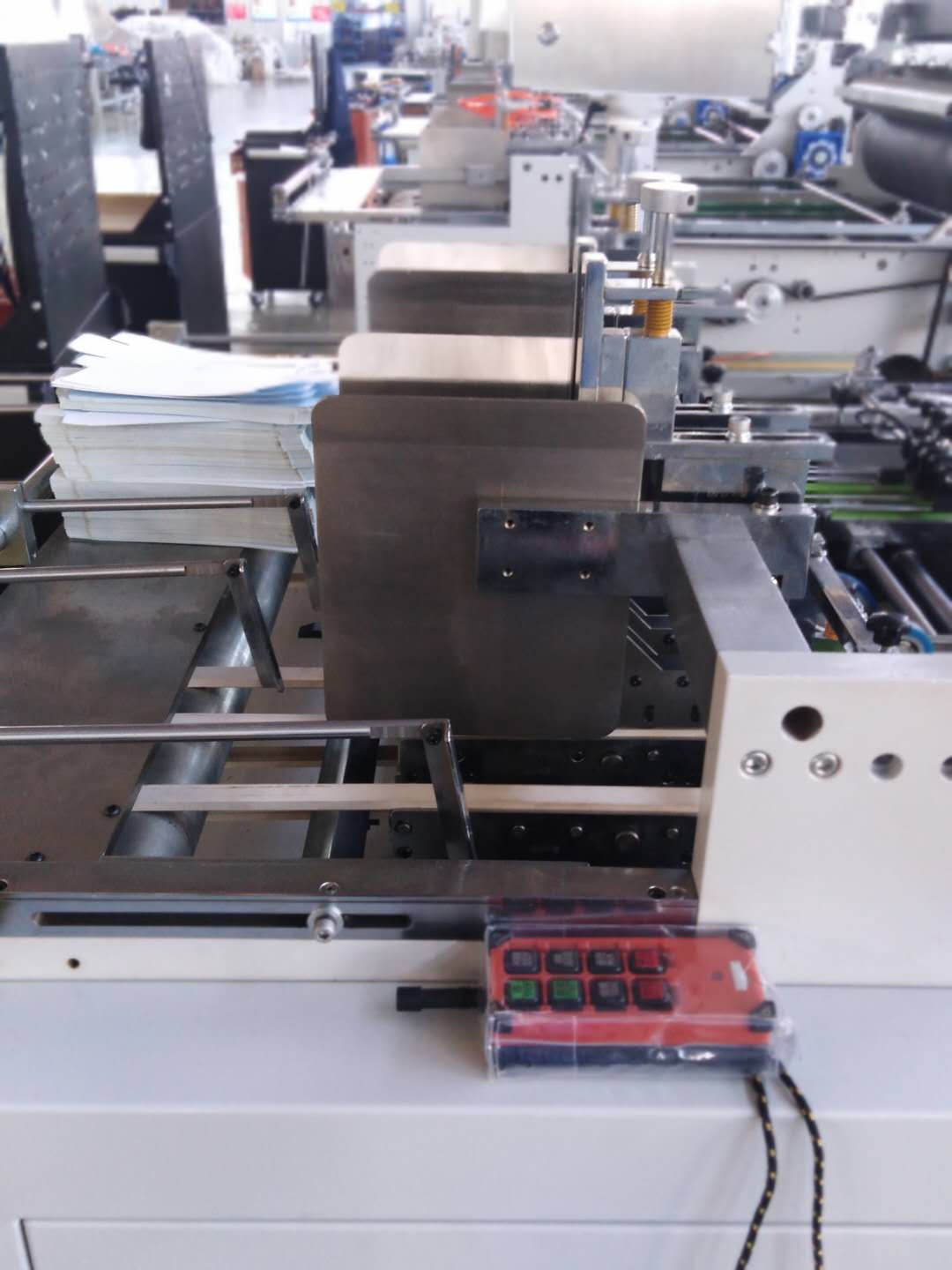

WINDOW PATCHING SECTION

Boxes are delivered from the gluing section to the window patching section by suction.

Suction is run individually and registered by sensor. When there is blank sheet, the suction table will go down to avoid sticking of glue on the belt.

Operator can adjust the volume of suction air according to the size of the box.

The suction cylinder is made of special material. It is smooth so that the speed of patching .

Its high and there will be no scratch on the plastic film.

When the knife cylinder is rolling, it intercrosses with another fixed knife bar and hence cutting the plastic film like "scissors". The cutting edge is flat and smooth.

The knife cylinder is with adjustable blowing or suction system to ensure the plastic film is patched on the window of the box accurately.

DELIVERY SECTION

The belt at the delivery section is wide. Operator can adjust the height of the belt and the finished products are aligned in a straight line.

The speed of the belt at delivery section can be adjusted as the same speed of the machine.

Copyright © 2012 SHM INTERNATIONAL 沪ICP备12034060号-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356