首页 > PRODUCTS > POSTPRESS SYSTEM > UV COATING MACHINEHS-106 UV Coating Machine

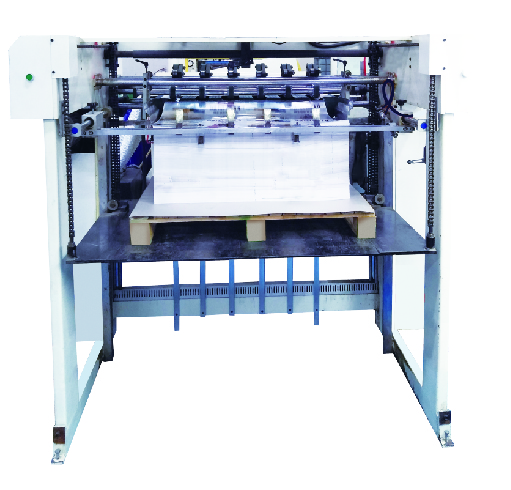

HS-106 UV COATING MACHINE

INTRODUCTION:

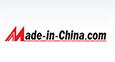

Our newly developed HS-106 is mesh-belt type varnishing machine, which applied upward swaying engaged method to deliver paper. It has the capacity of delivering 6,600 papers/hour. It accompanied with UV curing system. This machine has the features of high speed, high accuracy, high UV curing effiency and low power consumption.

MAIN SPECIFICATIONS:

|

Paper size |

Max.730x1060mm Min.310x406mm |

|

Coating size |

Max.720x1050mm |

|

Paper thickness |

100-450gsm |

|

Gripper margin |

5mm |

|

Printing speed |

Max.7000s/h |

|

UV power |

2x15kw |

|

IR power |

24x1kw |

|

Power |

|

|

Weight |

8500kg |

|

Dimension |

12000x3310x2240mm |

AUTOMATIC PAPER FEEDING SYSTEM

Employ highly reliable Feida branded paper sucker, which is able to output thin or thick paper smoothly.

Attach a sensitive detector which can tell double paper or paper lacking, and shut down machine immediately when abnormal paper output is seen.

Swinging-downward front lay or rotating side lay is used for paper positioning, which is accurate and reliable.

COATING MACHINE

The coating machine utilizes upward-swinging paper delivering approach, which enables stable paper delivery.

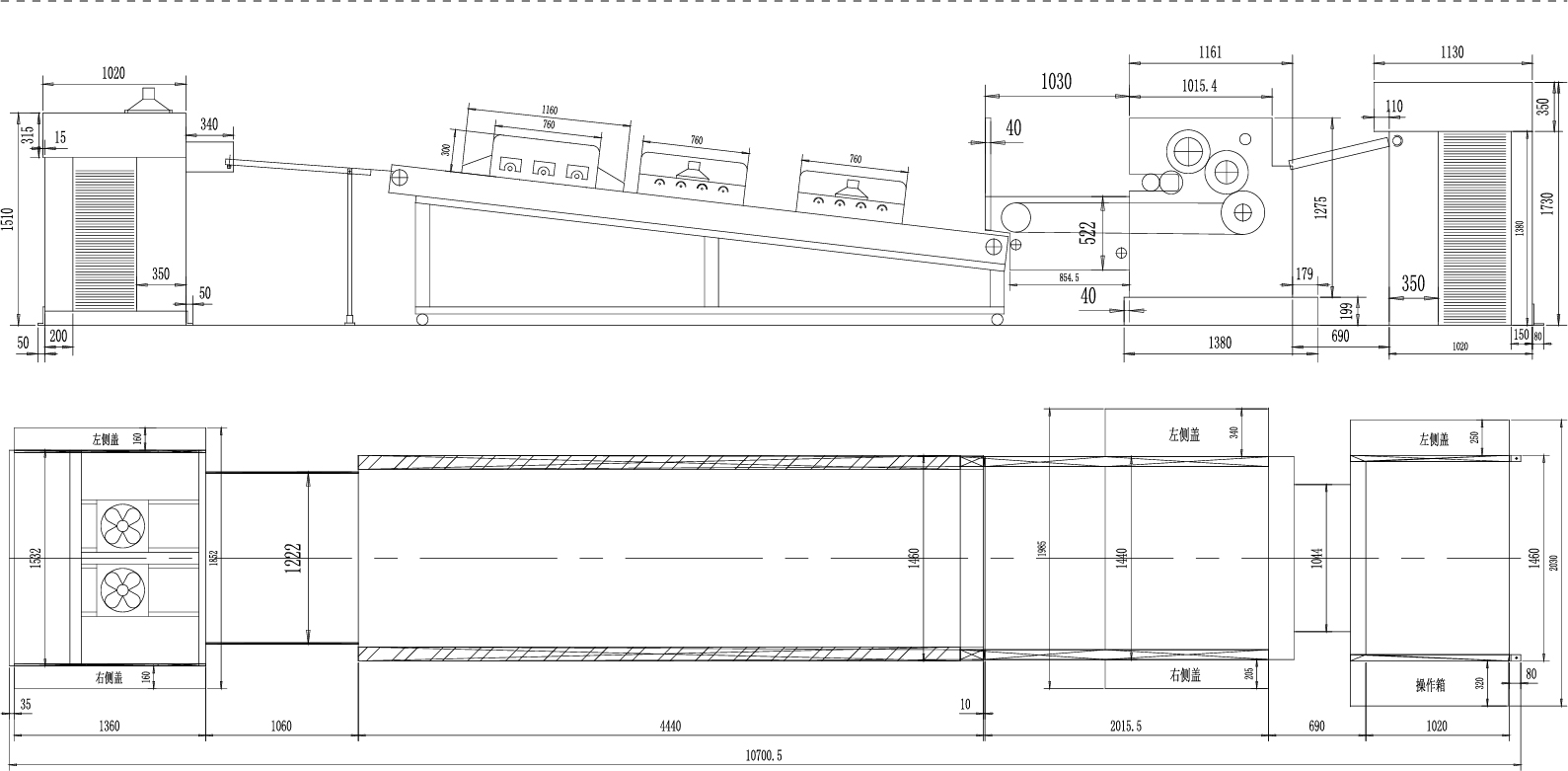

The coating machine roller utilizes fast plywood, which is more convenient.

Speed differential oil delivery system is used. Grid ceramic roller and chest-like scraper are alternative.

While paper flipping over, blower scratch-prevention device is used.

The coating machine uses imported precise bearing, which is reliable and easy to maintain.

UV DRYING EQUIPMENT

UV drier uses three sets of UV mercury light, which is able to solidify UV light oil quickly.

Switch of Full light or half light is available. UV ray leaking-prevention device is equipped. Light is off automatically if transmission grid is cut off, safeguarding people.

Auto temperature controller is installed internally. Cooling and air exhausting equipment is available if the electronic is tripping. UV light box rises and falls automatically in case of fire.

Teflon delivery belt is able to offset automatically. Alarm shall be called out provided any abnormality including off tracking occurs.

Vacuum-based absorption paper delivery is through the entire process, which guarantee stable paper.

The whole vacuum adsorption paper feeding, to ensure the stability of paper.

AUTOMATIC PAPER FEEDER

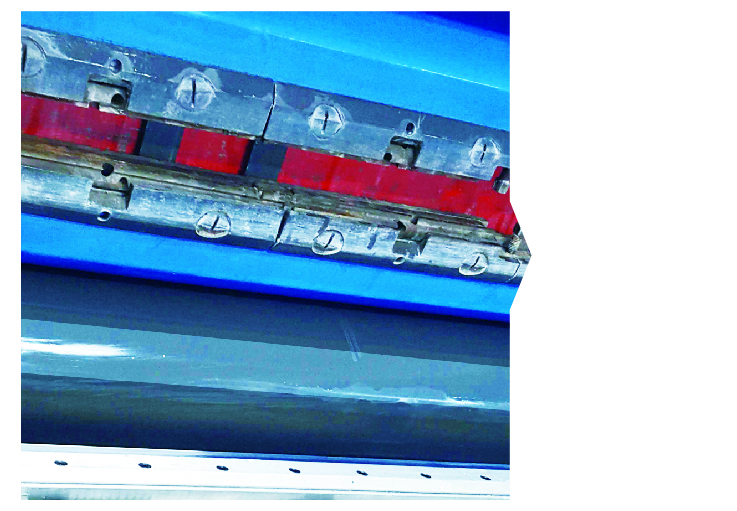

Pneumatic venting system with convenient regulation, enabling smooth and orderly paper collection.

Cooling fan is available, while AC cooler is also alternative.

Humanized counting alarm device, which has accurate counting and can set alarming paper numbers optionally.

Copyright © 2012 SHM INTERNATIONAL 沪ICP备12034060号-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356