KYD-1080/1300 Semi-auto full page stripping & Blanking machine

INTRODUCTION

This automatic machine has a powerful waste removal function completely, which can achieve one pass fully remove all waste after die cutting for different specifications of box types, windows, and aircraft holes, and material waste edges of front and back stitching as long as they are within the size requirements of machine.

This machine have the high quality for removing the waste completely in one pass, with fast efficiency, simple operation, increasing user’s production capacity.

KYD-1080 Semi auto full page stripping & Blanking machine

MAIN FEATURES

Machine can on time full remove the waste for front and back imposition of materials.

Save labor and save tool cost and mould cost.

Not need the mould for different product size, with the honeycomb plate frame and pins to adapt to the changeable box shape. The down pins support box area, the upper pins pressed on the waste area to remove the waste.

1 pass to stripping & blanking waste area completely, high effciency with simple adjustment, easy opertaion. Improve the user's production capacity greatly.

MAIN SPECIFICATIONS:

| Max material stack size | 1080 x 780mm |

| Max product size | 1060 x 760mm |

| Mini product size | 35 x 35mm |

| Max material stack height | 80mm |

| Max pressure | 100kn |

| Speed | 1-5times/min |

| Total power | 4kW |

| Average power | 2.8kW |

| Air consumption | 65L/min |

| Air press | 0.5-0.6Mpa |

| Voltage | 380V/3 phase / 50HZ |

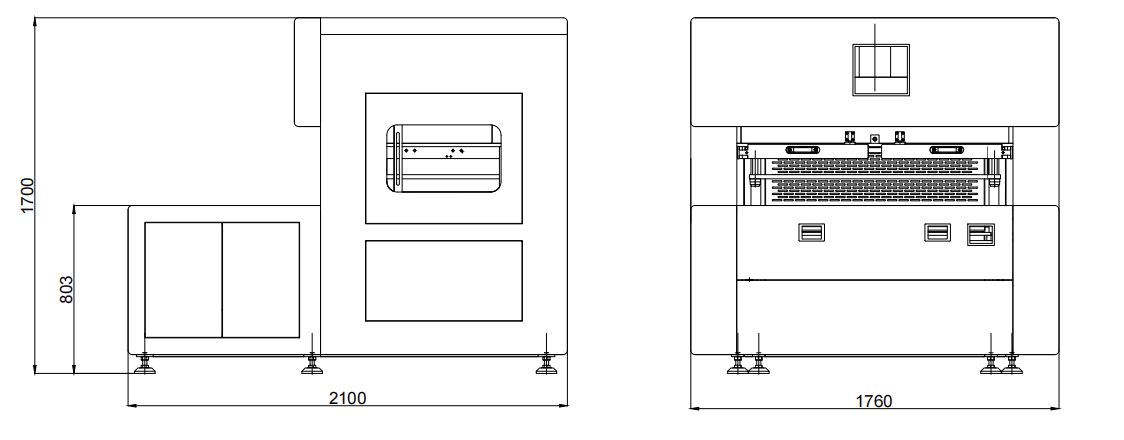

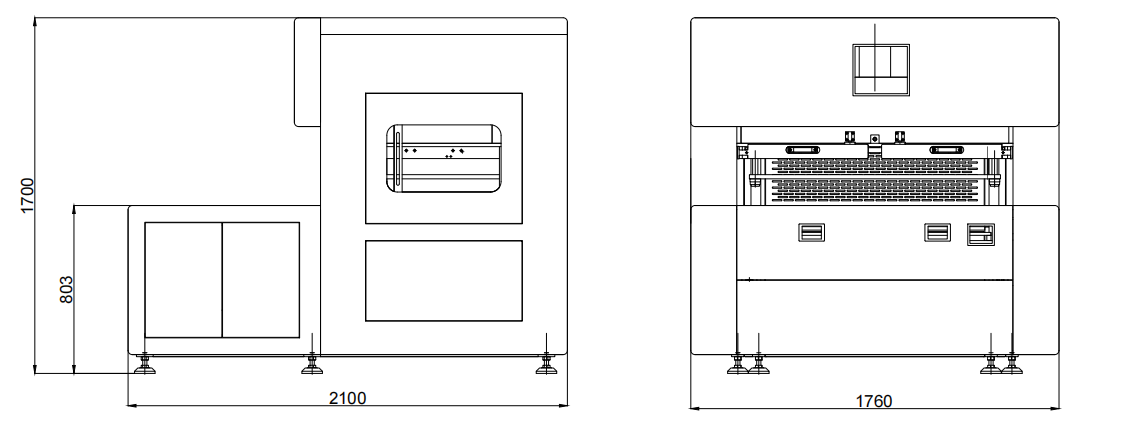

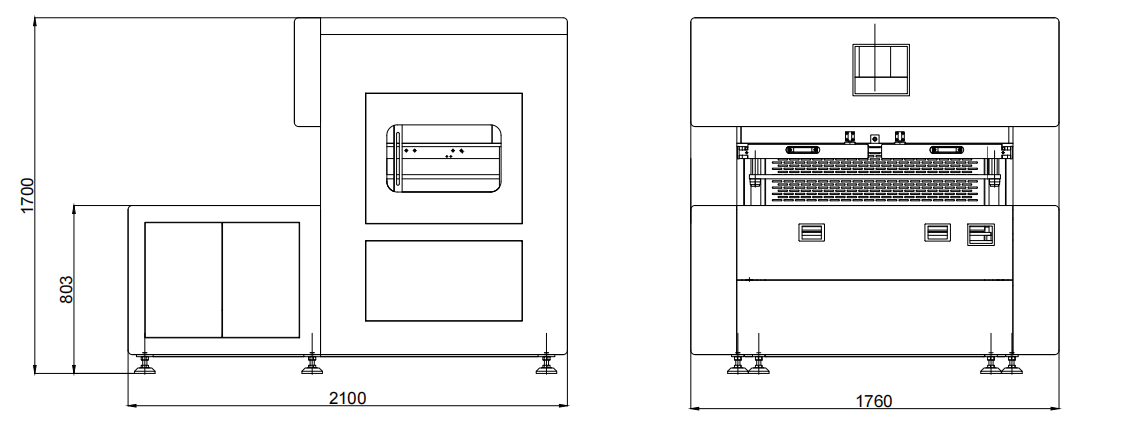

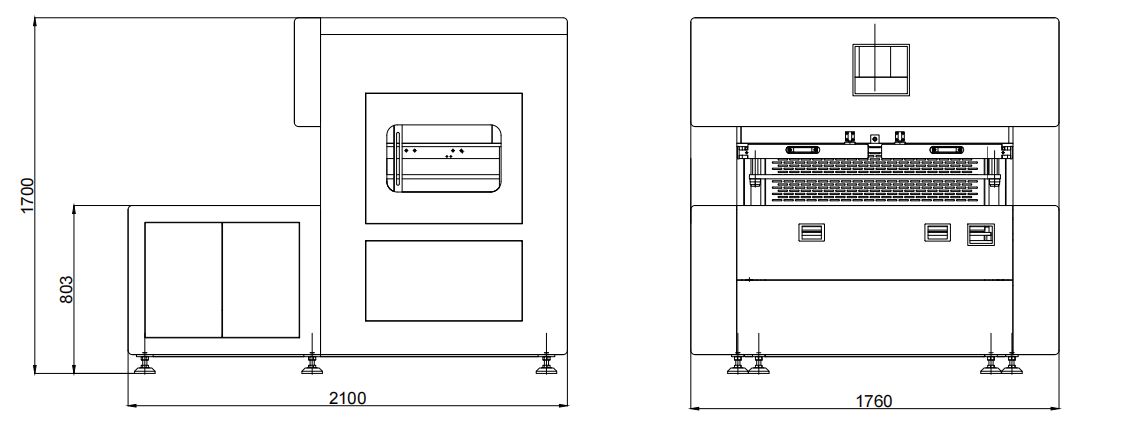

| Machine size | 2100 x 1760 x 1700mm |

| Weight | 2580kgs |

-

4pcs air cylinder in the 4 corner to control the lower working panel up & down movement

-

Main air cylinder to control the lower working panel in & out movement

-

Hydraulic Oil system to control the Up & down of upper working panel.

VANE PUMP

-

Upper pins to remove the waste parts and lower pins to hold the products part.

Diameter: 5mm* 500pcs

Diameter: 3mm *50pcsDiameter: 12mm* 500pcs

Diameter: 8mm * 50pcs -

Through Upper and Lower Pins to press and remove the waste of product with one time, Not need any mould for different size & different shape of box.