KYD-1080A Double function semi-auto stripping & Blanking machine

This automatic stripping & blanking machine has a powerful waste removal function completely with row blanking function, which can achieve one pass fully remove all waste after die cutting for different specifications of box types, windows, and aircraft holes, and material waste edges of front and back stitching as long as they are within the size requirements of machine.

This machine have the high quality for removing the waste completely in one pass, with fast efficiency, simple operation, increasing user’s production capacity.

| Max material stack size | 1080 x 780mm |

| Max material stack height | 80mm |

| Products size | 35 x 35mm --1060 x 760mm |

| Max pressure | 100Bar |

| Speed | 1-5times/min |

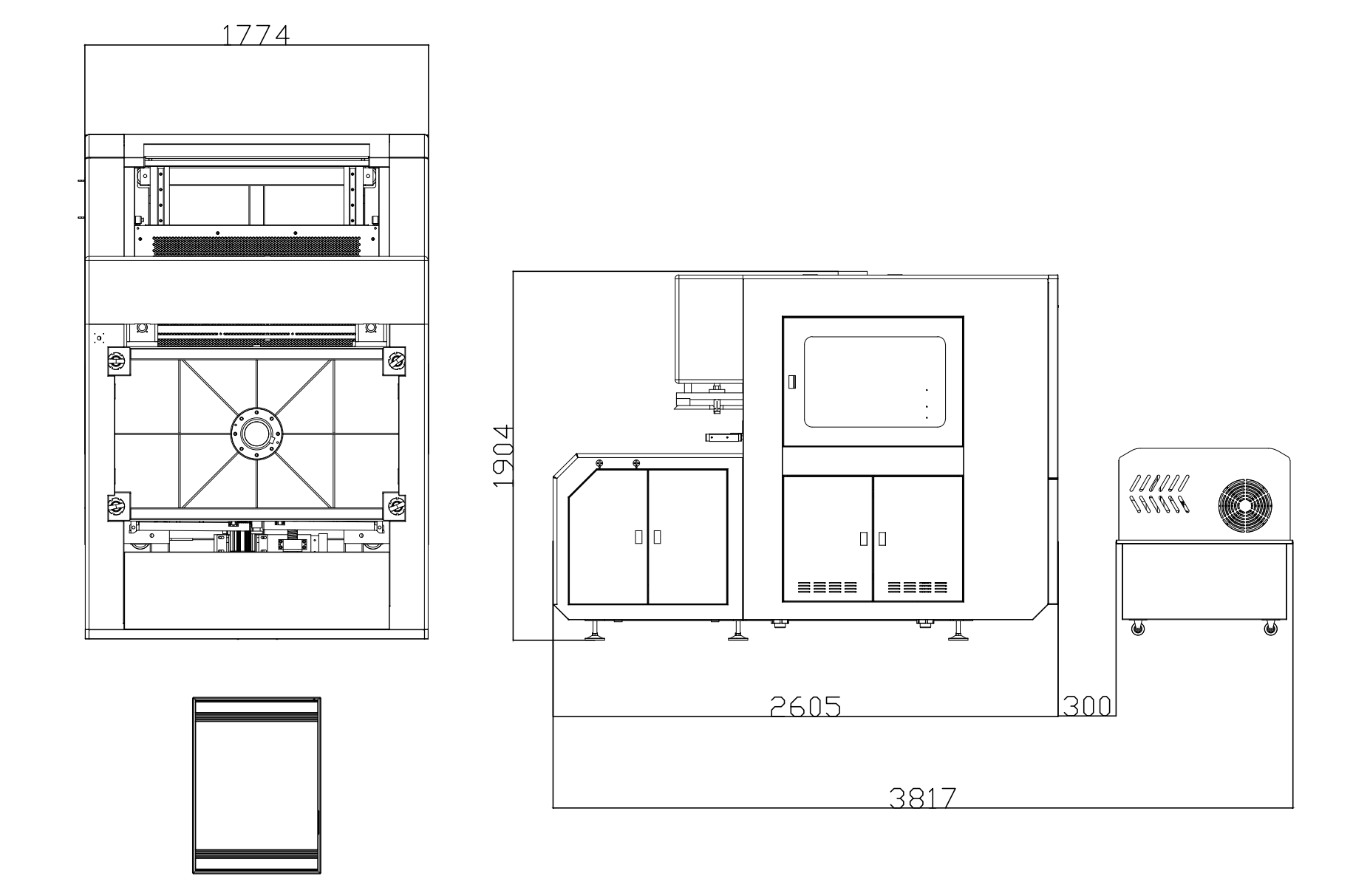

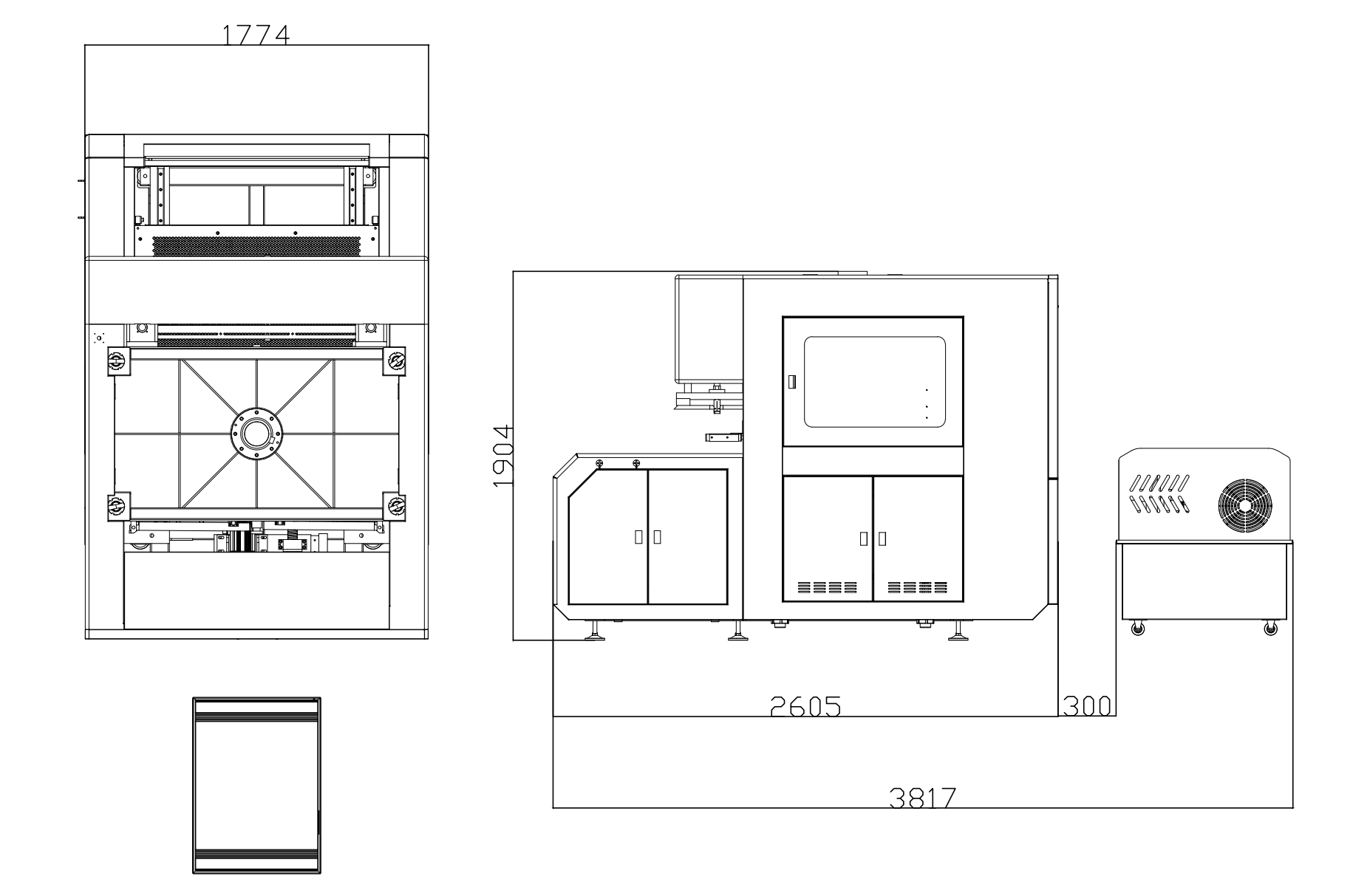

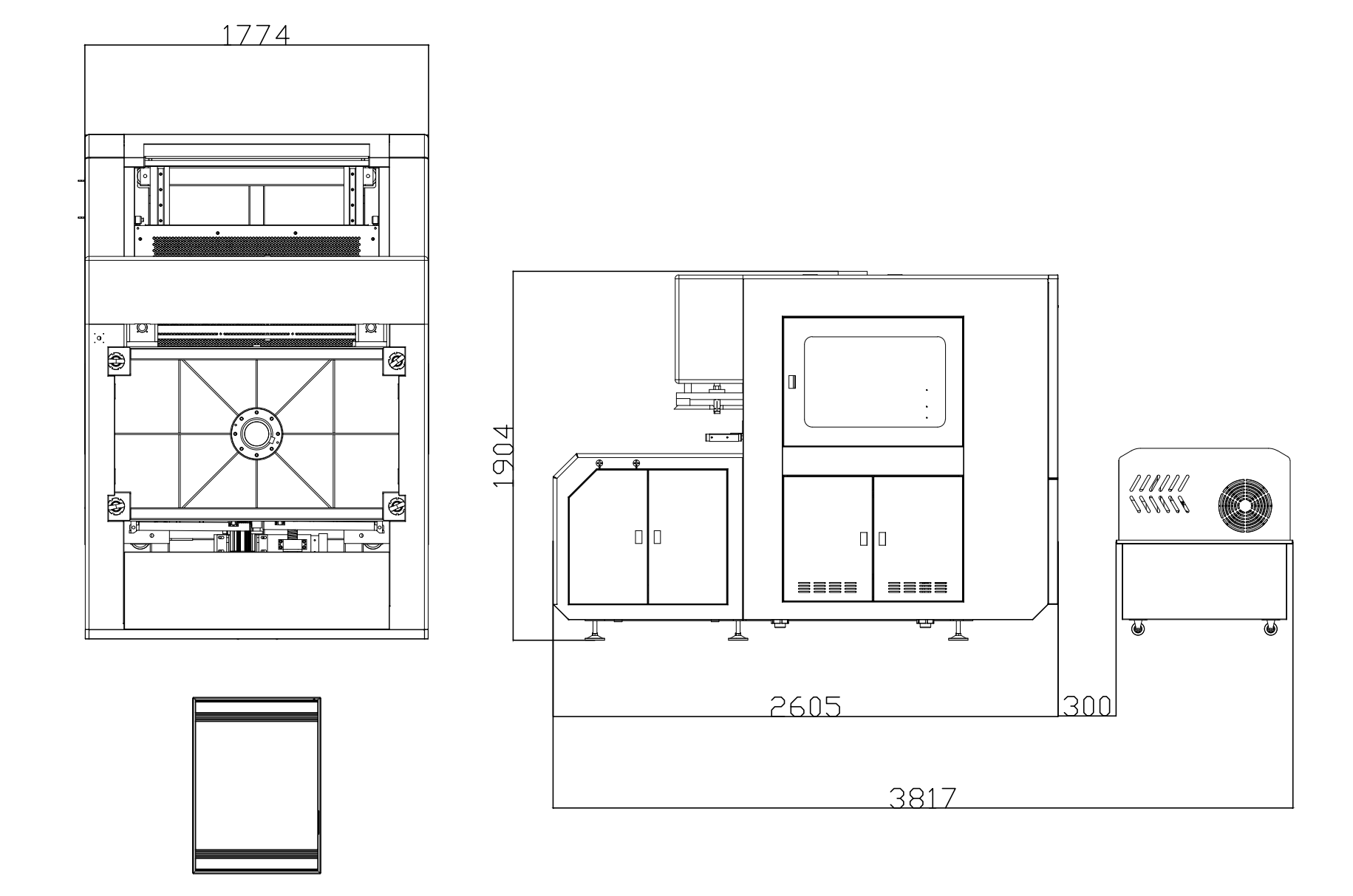

| Machine size | 2650 x 1800 x 2000mm |

| Weight | 3000kgs |

| Power | 380V/3phase/50HZ/10kW |

| Air consumption | 2L/min |

| Compressed Air | 5-6Bar |

-

Electrical part

-

Cylinder

-

High protections of installed Grating protector, with CE standard, high precision sensor on the feeding 2 side for protecting, and double OFF/ON buttons operation.

-

Machine use the Vane type hydraulic pump to make sure the stability of machine working pressure.

-

Row Stripping Function

Upper metal fingers to press on the waste part & not-working part

Lower pins to hold the products part . Lower Pins diameter: 12mm & 8mm -

Whole Blanking Function

Through Upper and Lower Pins to press and remove the waste of product with one time, Not need any mould for different size & different shape of box.

Upper pins to remove the waste parts. Diameter: 5mm & 3mmLower pins to hold the products part. Diameter: 12mm & 8mm

-

Machine use high strong structure

High precision frame of machine is more strong and ensure the machine main body strong loads. 4 pcs of 80mm diameter main frame Pipe can hold 80tons pressure.

-

Servo motor drive the 50mm diameter Lead screw to make sure the working table In & Out motion it is high stability and precise.